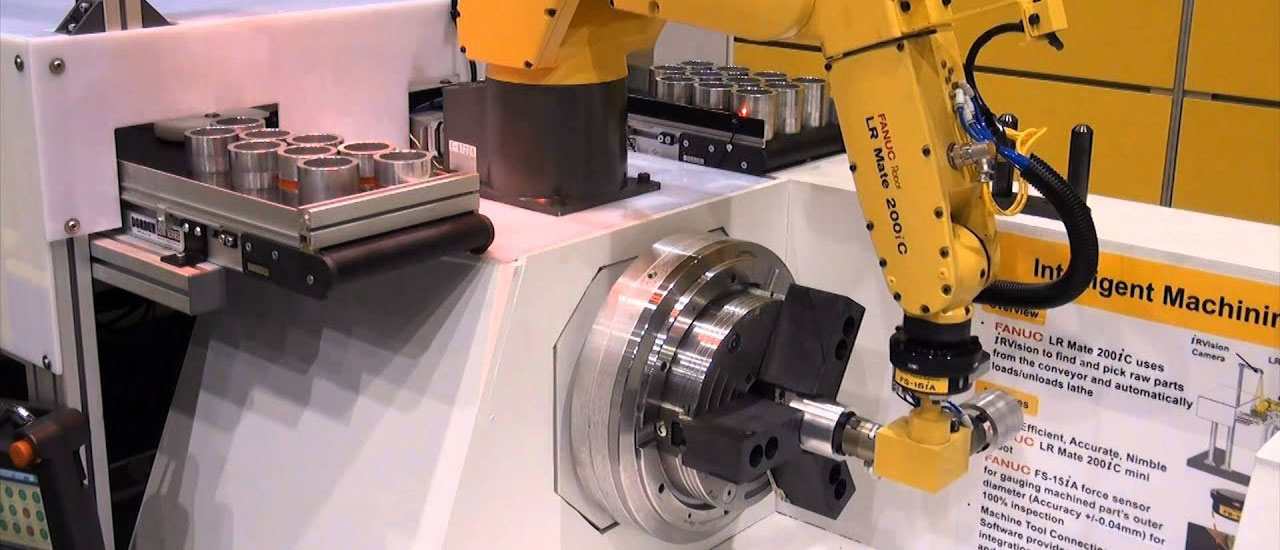

This type of robot is fully customized. We can specify the exact I/O cards and interface it in the most efficient way. We do not have to know how to use the existing machine tools ladder and interface points. We can upgrade them easily. We also do not need to figure out the existing logic of the machine tool to attempt to design around the current function. Machine tool builders often have ladder updates and when they install them they could write over the logic we installed, therefore causing many problems trying to reinstall and track ladder mods within main ladder.

This type of robot is fully customized. We can specify the exact I/O cards and interface it in the most efficient way. We do not have to know how to use the existing machine tools ladder and interface points. We can upgrade them easily. We also do not need to figure out the existing logic of the machine tool to attempt to design around the current function. Machine tool builders often have ladder updates and when they install them they could write over the logic we installed, therefore causing many problems trying to reinstall and track ladder mods within main ladder.

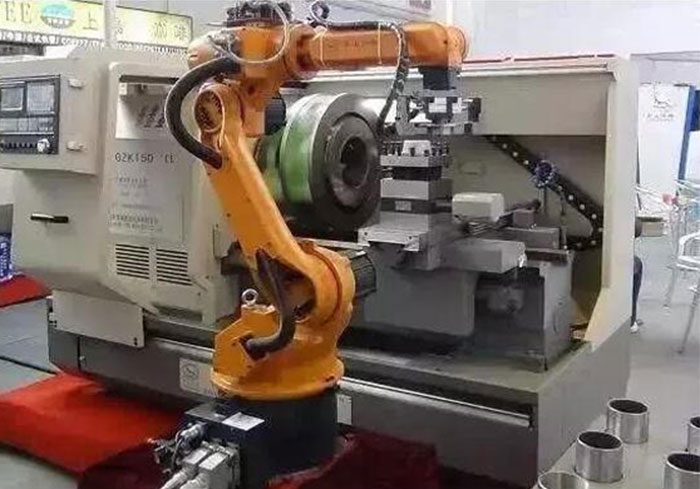

More signals given from machine tool to a terminal strip. There is no need to splice into wires to get signals and figure out safety circuit. Less hardware and costs of additional panel. Cleaner interface between robot and machine. Industrial robots are usually integrated and interfaced with machine tools to increase the efficiency of the down time and reduce manual work.We customise and design built-to-order robots according to client’s requirements from an external vendor, usually overseas. Then we manufacture the mounting brackets and other accessories for the robot’s positioning and mounting based on the specification of the machine. We then modify the gripper of the arm based on the machine components and then assemble it. Finally, we teach the robot its position and program it accordingly.